• Cells: follow UN/DOT 38.3

•small cells/batteries (150g/6ms, 3 axis, +/-, 3X repeat)

•large cells/batteries (50g/11ms, 3 axis, +/-, 3X repeat)

• Packs: 25g, 18 ms, 3 axis, +/- directions, 3X repeat) No rupture, fire, explosion, or loss of isolation

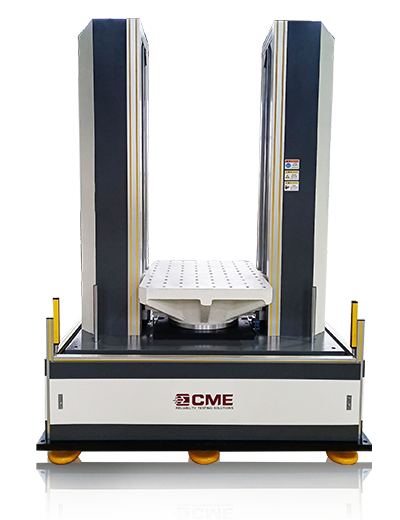

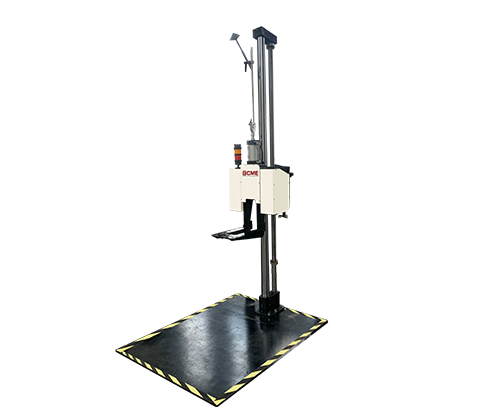

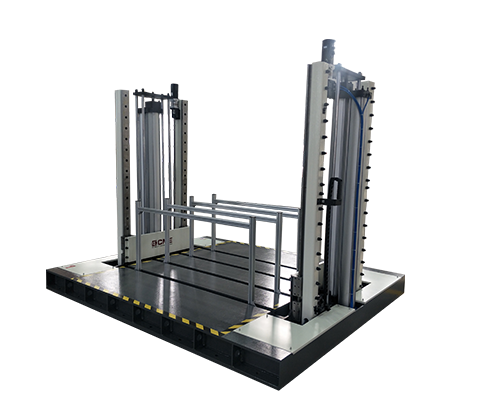

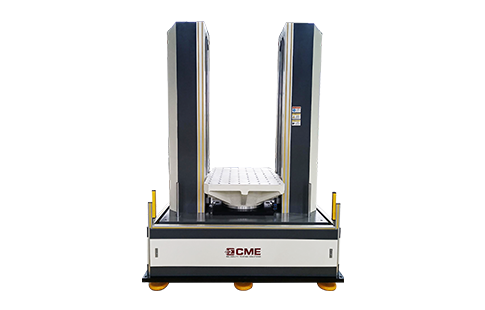

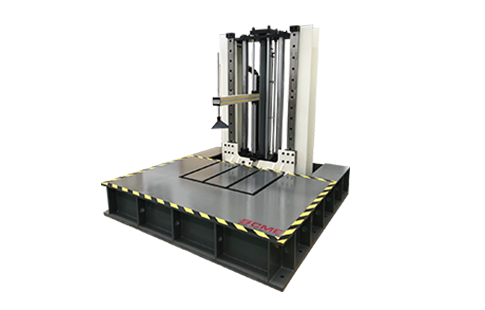

4.5 Mechanical Shock

Rationale: This condition simulates inertial loads which may occur during a vehicle crash situation. The battery system shall meet the requirements in 4.5.3 when tested according to one of the following two alternatives.4.5.1 Alternative 1: Battery System-Level Evaluation

Condition: The complete battery system is to be tested, with the following exceptions/ clarifications, in accordance with one of the following options: UN Test Manual,Test T.4; or SAE J2464, Section 4.3.1.

Exceptions/Clarifications: Evaluations, one repetition each, are to be conducted in the positive and negative directions of the primary vehicle longitudinal and lateral axes, as installed, for a total of 4 separate evaluation conditions. it is not required that all evaluation conditions be conducted on a single test sample.

The battery system shall be firmly secured to the test fixture. Note that, while battery modules or sections may be individually tested in accordance with UN requirements, a complete battery system is to be tested for this condition, except as allowed per 4.1.3.

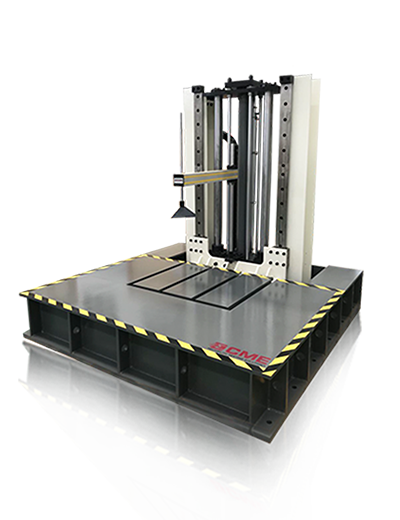

NOTE: For battery systems with mass >100 kg, a shock test may need to occur using a crash simulation sled, or similar device.

4.5.2Alternative 2: Vehicle-Level Evaluation

Condition: The complete battery system is to be assessed following vehicle tests simulating front, rear, and side impacts, as defined in FMVSS 305,S6.1,6.2,6.3 (or equivalent regionally applicable vehicle front, rear, and side crash conditions)with the following exceptions/clarifications:

Battery state of charge (SOC) shall be at 95-100% of the maximum which is possible during normal vehicle operation and battery temperature shall be 25 C±5°C(or as specified in equivalent regionally applicable regulations).

4.5.3 Requirements

The following requirements are to be met following the test for either alternative selected.

During the test and for a minimum 1 hour post-test observation period, the battery system shall exhibit no evidence of battery enclosure rupture, fire,or explosion and shall maintain high voltage to ground isolation of no less than 100 Qv.lsolation measurements are to be done in accordance with ISO 6469-1,6.1.3; or equivalent. For Alternative 2, the battery system shall be retained at its mounting location (per SAEJ1766, Section 4.4.2).