The advantage of the pyrotechnic product explosion method simulation test technology is that it can produce the most accurate simulation results, and can produce the high acceleration and high frequency range unique to the near-zone explosion shock environment. The main disadvantages are high test cost, poor safety and large dispersion of loading levels.

Shock environment is a transient physical accelerating, such as impact, free-fall, kick, earthquake, or explosion.

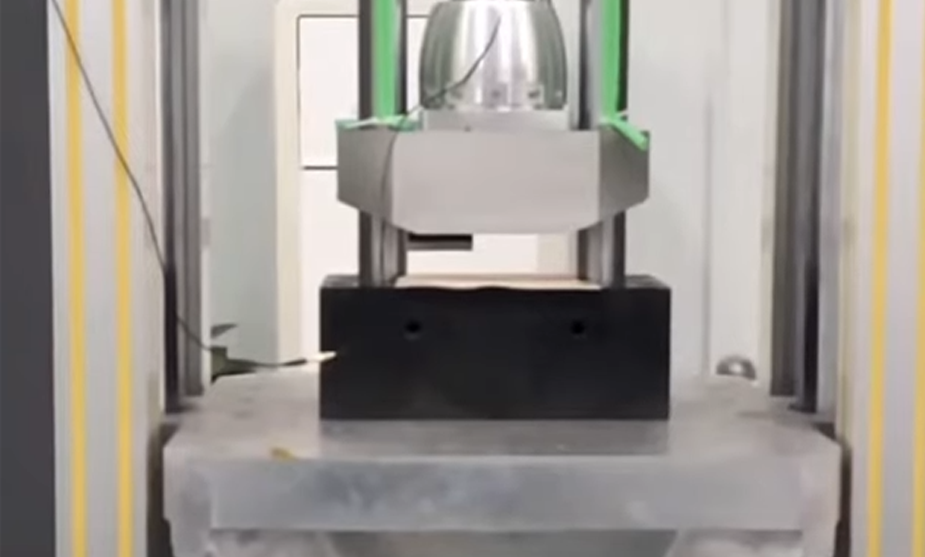

A shock pulse can be characterized by its peak acceleration, the duration, and the shape of the shock pulse (half sine, post-peak sawtooth, trapezoid, etc.).

There are various shock phenomena in the production, transportation and operation in various industries such as aviation, aerospace, navigation, weapons, and electronics, which have a great negative impact on the quality and reliability of the products. In order to solve this problem, a shock test was produced and developed on this basis. After more than one hundred years of development, the shock test technology has become quite mature, and it also plays an irreplaceable role in national defense and civil industries.

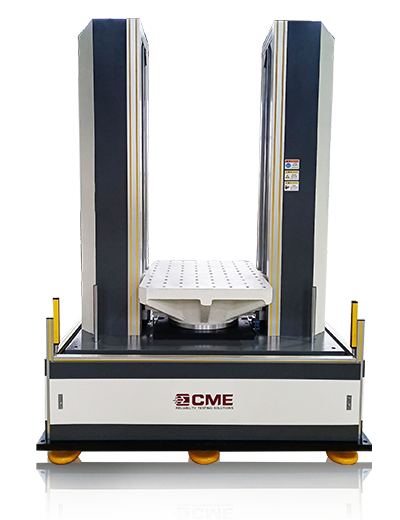

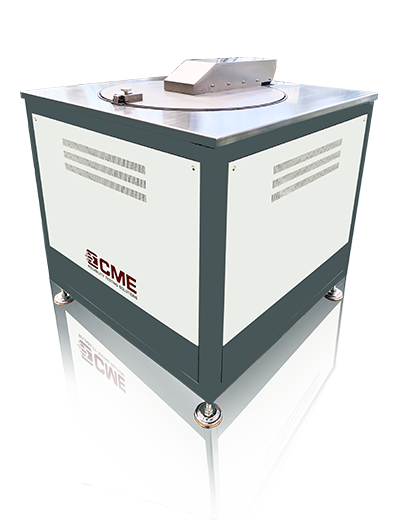

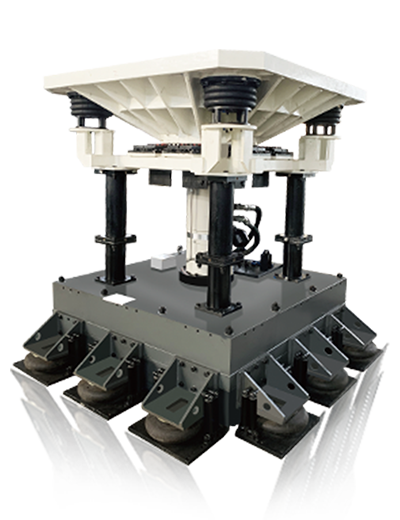

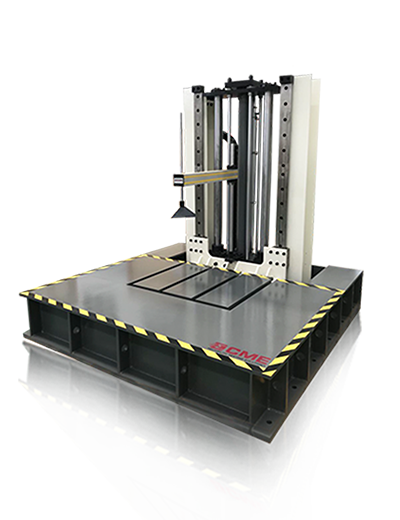

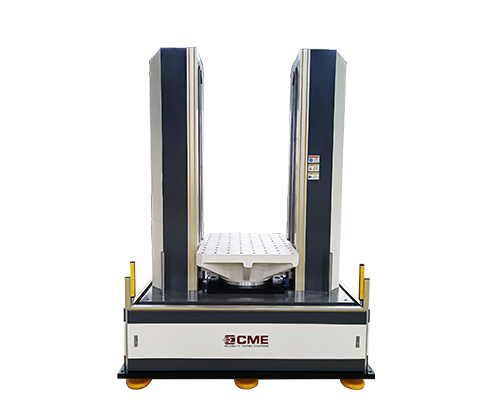

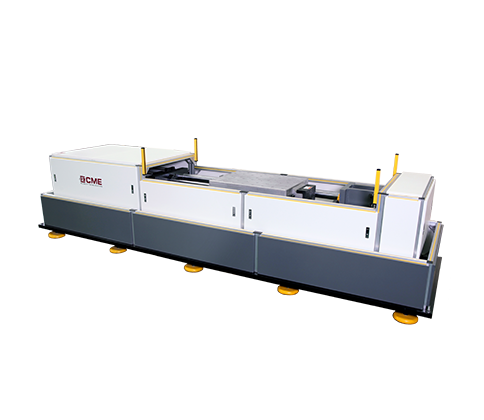

CME offers high-quality shock test equipment for sale at good prices. Welcome to contact us!