Overview

The standard MIL-STD-810F clear the purpose of the centrifuge acceleration testing: "It is used to determine the force (except gravity) produced by components, equipment and other electrical and electronic products subjected to a steady-state acceleration (constant acceleration) environment. For example, under the action of running vehicles, aerial vehicles, rotating machinery, and projectiles, whether the adaptability and performance of the structure in good condition, and to evaluate the structural integrity of some components." Constant acceleration test can also be used to determine the effect of constant acceleration of microelectronic devices is to show structural and mechanical defects that may not be detected during shock and vibration test. It can also be used as a high-stress test to determine packaging, internal metallization and lead systems, chip or back cover adhesion capability and structural strength limit values of other components of microelectronic devices. It can be said that the constant acceleration test is a more scientific test loading program and specific operation method used to assess whether the product meets the above requirements and guarantees a certain reproducibility of the test.

There are two standard types of centrifugal constant centrifuge acceleration testing machines. One is the centrifugal box type, which is suitable for the constant acceleration test of small electronic components and microelectronic devices; the other is the centrifugal arm type, which is suitable for the constant acceleration test of electrical and electronic product components and small complete machines.

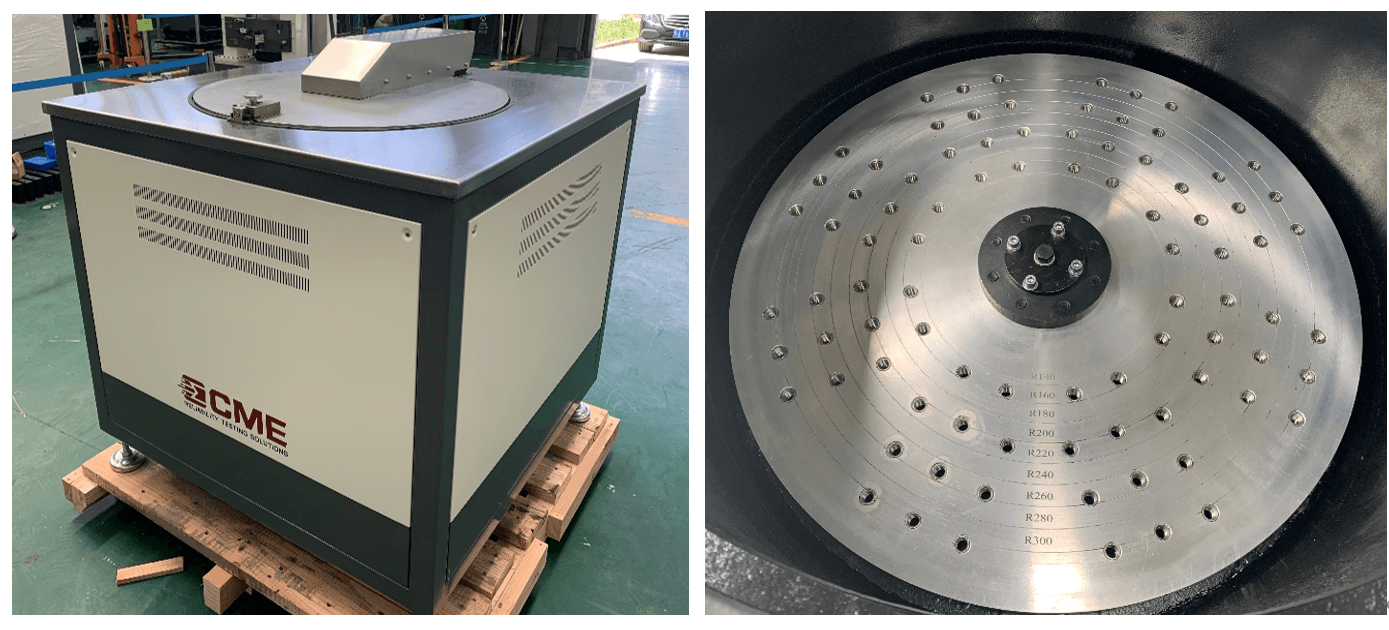

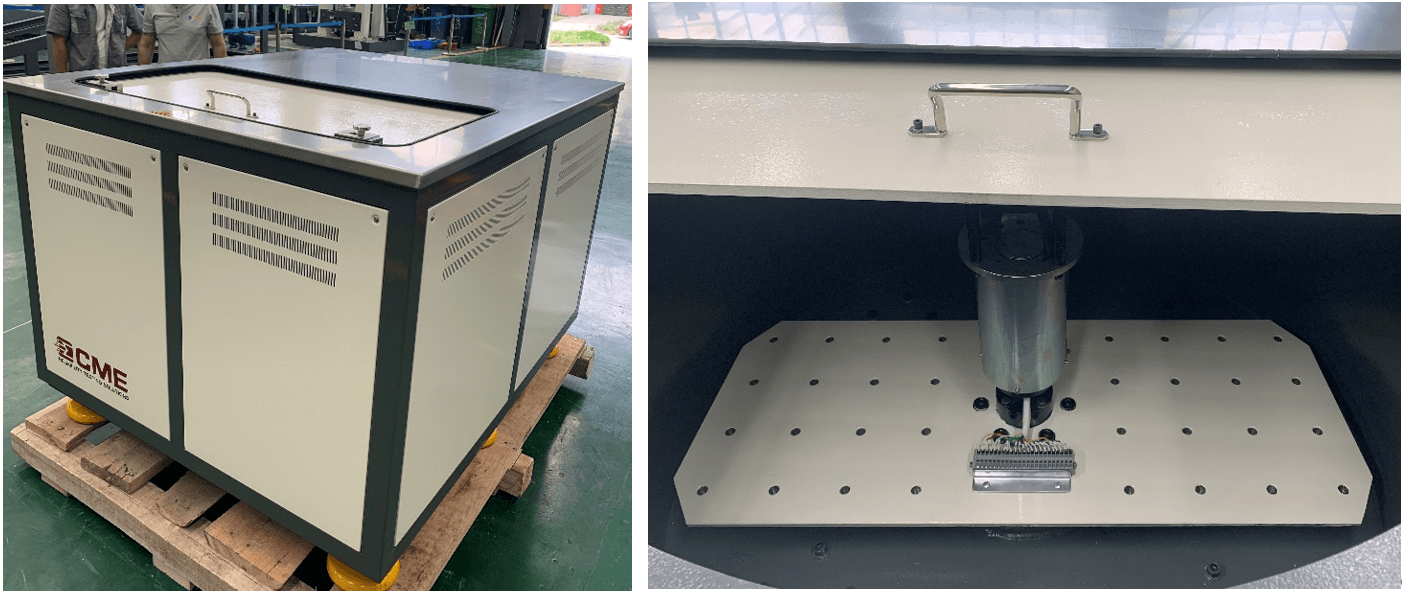

CME offers two types of standard centrifugal constant acceleration tester (box type):

1) KRD30-03/05: krd30 is a small standard rotation centrifuge. KRD30-03 is a six-station and KRD30-05 is a four-station. It is equipped with 12-ring conductive slip ring as standard, and the acceleration is up to 500g.

2) KRD30-10/20: it is a small arm centrifuge, both models are two-station, with 12 conductive slip rings as standard, and the maximum acceleration is 100g.

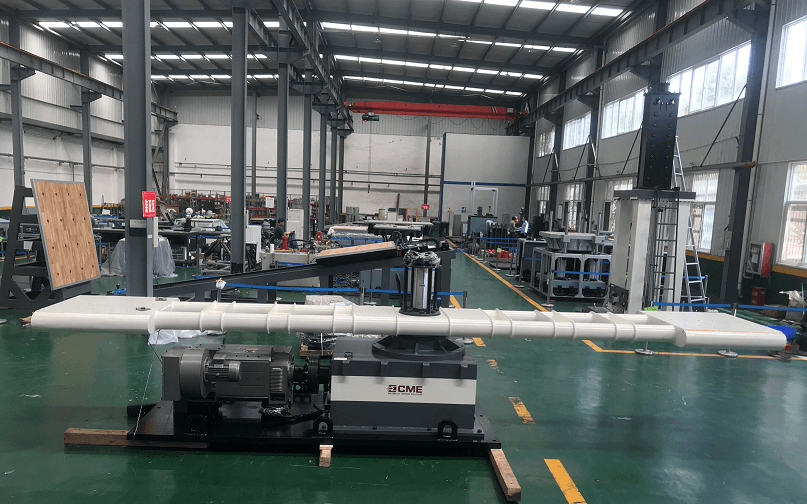

KRD31 series are the arm type centrifugal constant acceleration tester:

In addition, with the development of military industry and technology, there are more and more constant acceleration tests. At present, the common non-standard centrifuges mainly include the following:

(1) High-speed rotation centrifuge: This type of centrifuge is driven by an electric spindle to achieve the required speed. Commonly used for centrifugal tests of batteries. According to different test requirements, it can be roughly divided into 15,000 rpm, 20,000 rpm, 30,000 rpm and 50,000 rpm centrifuges. The load of this type of equipment is generally small, and the size of the sample is also small.

(2) Dual-environment centrifuge: This type of centrifuge provides a platform for the sample to revolve and rotate, that is, while the sample is rotating, it revolves around a fixed axis of a certain radius. It is called a dual-environment centrifuge or dynamic overload testing machine.

(3) Centrifugal shock compound testing machine: This type of centrifuge is mostly used to simulate the real motion state of missiles or shells after launching, that is, the sample is rotated at high speed while making it bear sufficient shock acceleration and overload. Generally, it is a high-speed spinning centrifuge. A composite test system composed of a high acceleration shock table.

(4) Centrifugal vibration compound testing machine: This type of centrifuge is an urgently needed environmental testing equipment in the fields of geotechnical technology, earthquake simulation and aerospace. For example, when the spacecraft is orbiting the earth, when the aircraft is climbing, diving and hovering, and when the strategic missile is in the active phase and passing through the reentry phase, its internal equipment and devices are subjected to the combined action of acceleration overload and engine vibration. Its basic structure is to load the shaking table on the rotating arm of the centrifuge, so that the sample is subjected to the centrifugal constant acceleration test at the same time during the vibration test. This system can also be extended to a comprehensive test system of centrifuge, vibration shaker machine table and climate chamber.

In short, no matter which kind of constant acceleration centrifugal testing machine, its basic parameters are the same, as long as we understand its basic parameters, we can understand its overall function and performance.