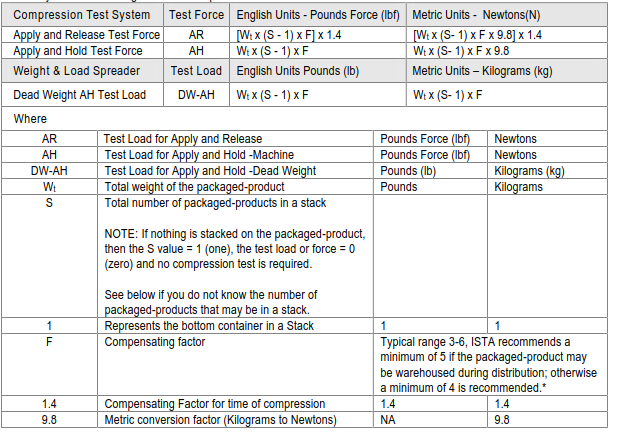

Package testing or packaging testing involves the test and measurement of a characteristic or property involved with packaging. This includes packaging materials and components, packaging shape, shipping containers, and unit loads, as well as the associated processes and environments.

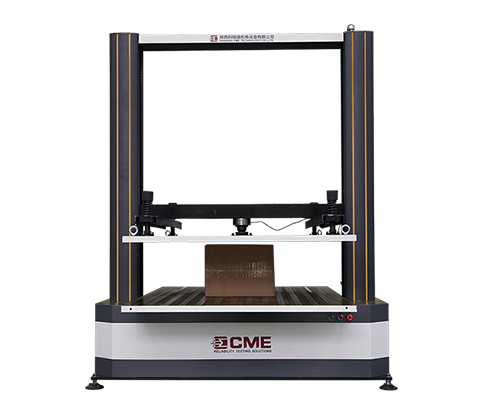

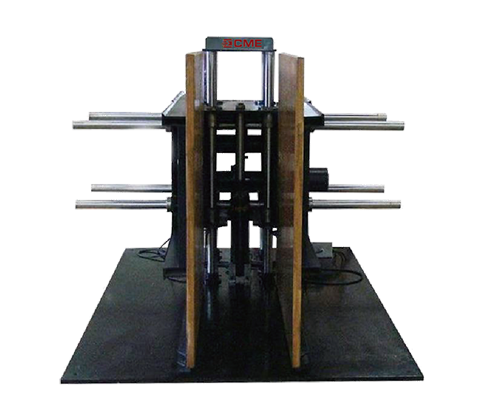

Packaging testing evaluates packaging suitability for product cushioning or support materials. Put the packaged product through a series of experiments to determine whether the packaging material will protect the product from damage. Package testing can be performed on the individual boxes or entire shipping containers to measure unit loads and movement during shipping.