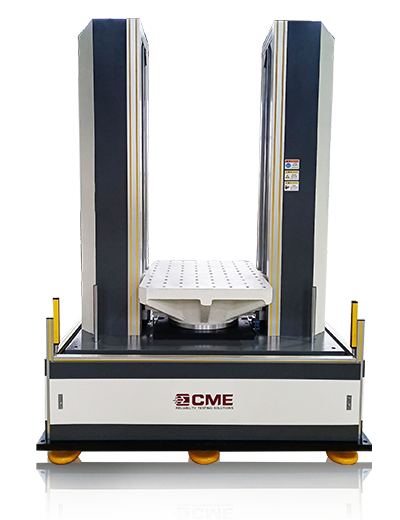

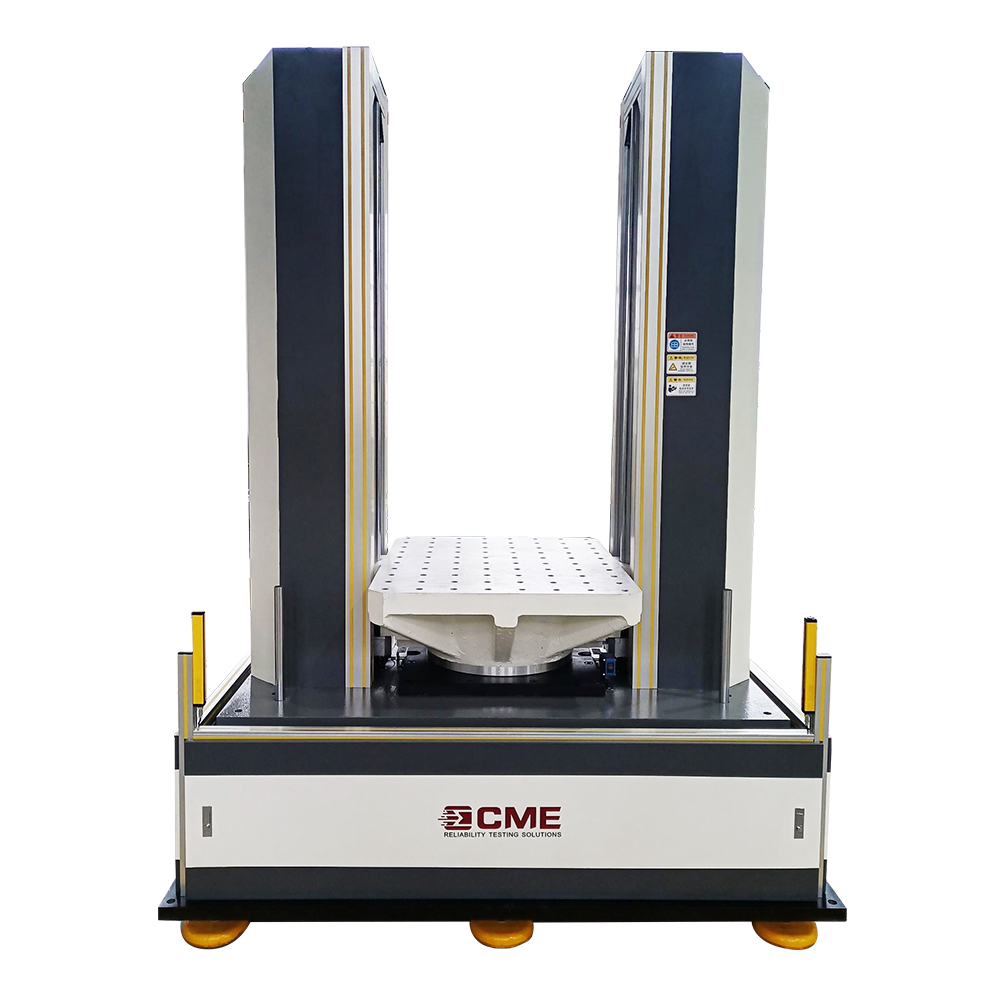

TABLE OF KRD11 PNEUMATIC VERTICAL SHOCK TEST MACHINE

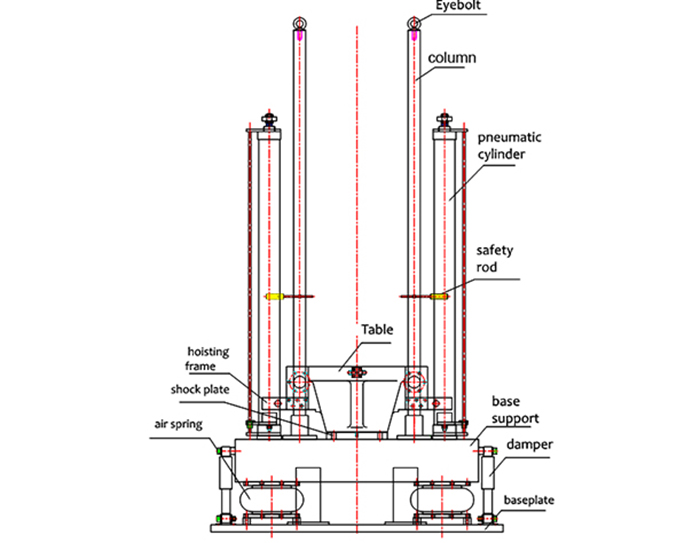

The test sample is installed on the worktable, which is guided by two high-precision sliding guides and can move up and down. The two cylinders are connected to the worktable by sliding guides. When the cylinders are inflated, the piston rod rises to drive the worktable to lift. The workbench is lifted. When it is raised to the set height, the cylinder quickly deflates, and the bottom surface of the worktable hits the waveform generator to complete a shock process.

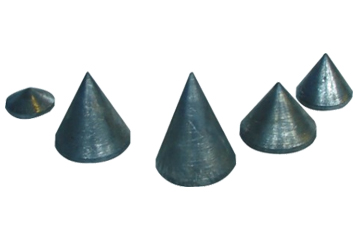

By adjusting the rising height of the worktable, different initial shock speeds can be obtained, and thus different shock overload values can be obtained; while changing the stiffness of the waveform generator, different pulse width values can be obtained. The structure schematic diagram is shown in following figure: