Procedure ISTA 3E is a general simulation test for unitized loads of similar retail or institutional packaged-products shipped from a manufacturing location to a distribution center. The unitized loads of packaged products are shipped through a motor carrier (truck) delivery system, where an entire trailer-load is filled with unitized packaged products, often of similar retail packaged products, intended for one destination. This type of shipment is called Full Truckload (FTL).

Definition of unitized load

A unitized load is defined as one or more products or packaged products usually on a skid or pallet, but always secured together or restrained for distribution as a single load. Examples include:

- A stretch wrapped pallet load of individual containers

- A single non packaged machine banded to a pallet

- A pallet with a corrugate tray, tube and a cap.

Each sample must be tested in the following order:

1. Atmospheric preconditioning, required

2. Atmospheric conditioning, optional

3. Shock test. It is required to choose an incline impact (1.2m/s) or a horizontal shock (1.2m/s).

4. Rotational edge drop test, required, height varies with packaged-product weight.

5. Compression test, required.

6. Random vibration test, required.

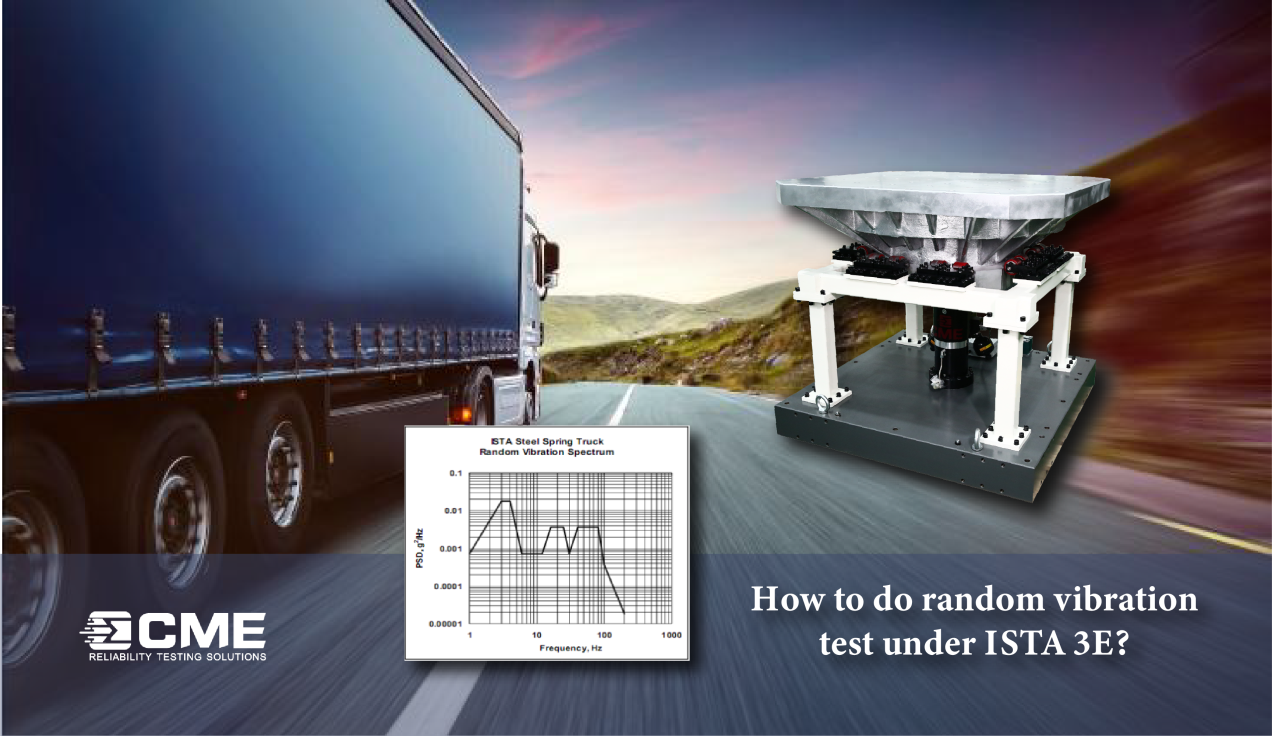

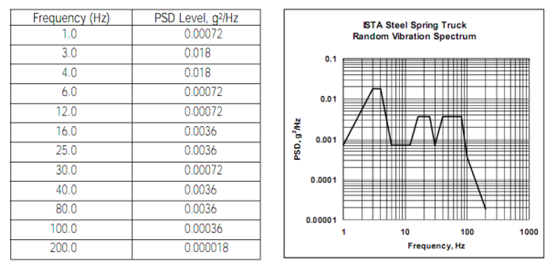

The ISTA Steel Spring Truck Random Vibration

The test is performed under ‘top-loose load’ conditions, no restrict on load vertical direction.

The random test Grms is 0.54, the theoretical P-P displacement is 45.13mm, as following:

Calculate the test time

Estimate the transportation distance of the package during land transportation, and then use the following formula to determine the test time:

Test time (minutes) = transportation distance (miles) ÷ 5. The longest test time is 240 minutes

or

Test time (minutes)=transportation distance (km) |÷8. The longest test time is 240 minutes

For example:

If the estimated transportation distance is 750 miles, the test time is 150 minutes. If the estimated transportation distance is 1000 kilometers, the test time is 125 minutes.

Choose suitable product to do vibration test

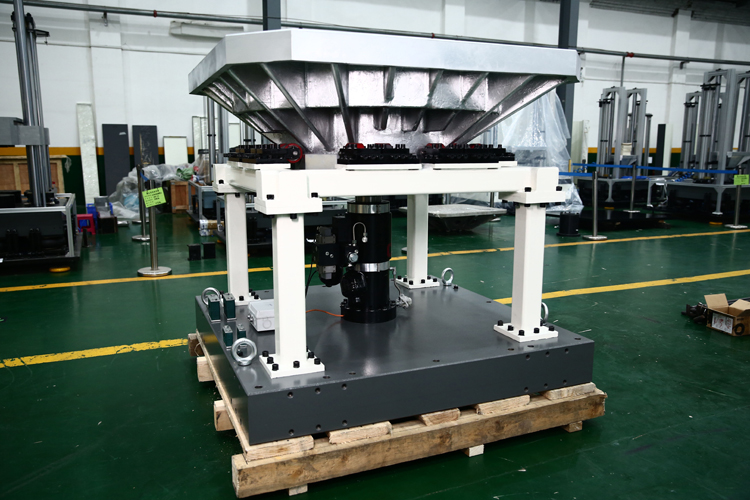

CME KRD70 series hydraulic vibration shaker can perfectly perform above test, while the normal electronic-dynamic shaker is difficult to meet long stroke and low frequency test, hydraulic shaker is the proper one to do this test.

KRD70 series hydraulic vibration shaker

The ista 3e standard testing can be used to: Evaluate the stability of the load, Determine the protective performance of packaging and packaged-products in relation to shock, vibration, and other stresses. Evaluate some conditions of transit, including pressure, moisture, and unusual handling. It is important to remember that the product and package are considered together rather than separately with 3E testing.

The ISTA 3E is the best test method to use for predicting the FTL (Full Truckload) Shipping Environment.

Have any inquiries about the mechanical vibration shaker? Please contact our sales: sales@cmetechnology.com for more information!