TABLE OF KRD10 HYDRAULIC VERTICAL SHOCK TEST SYSTEM

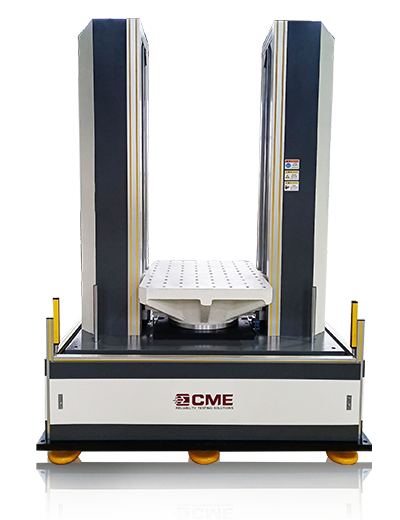

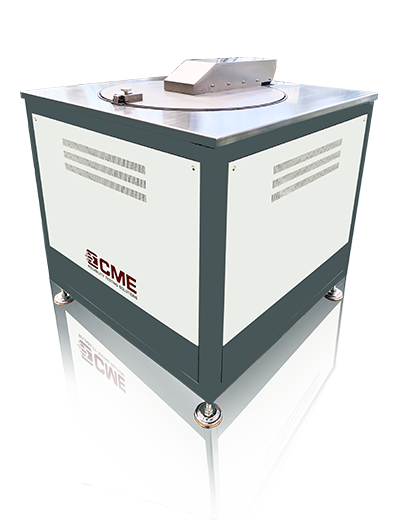

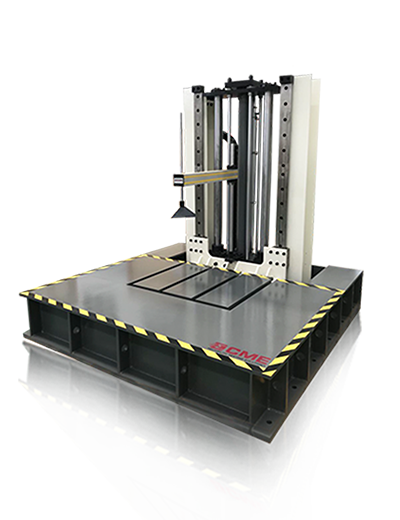

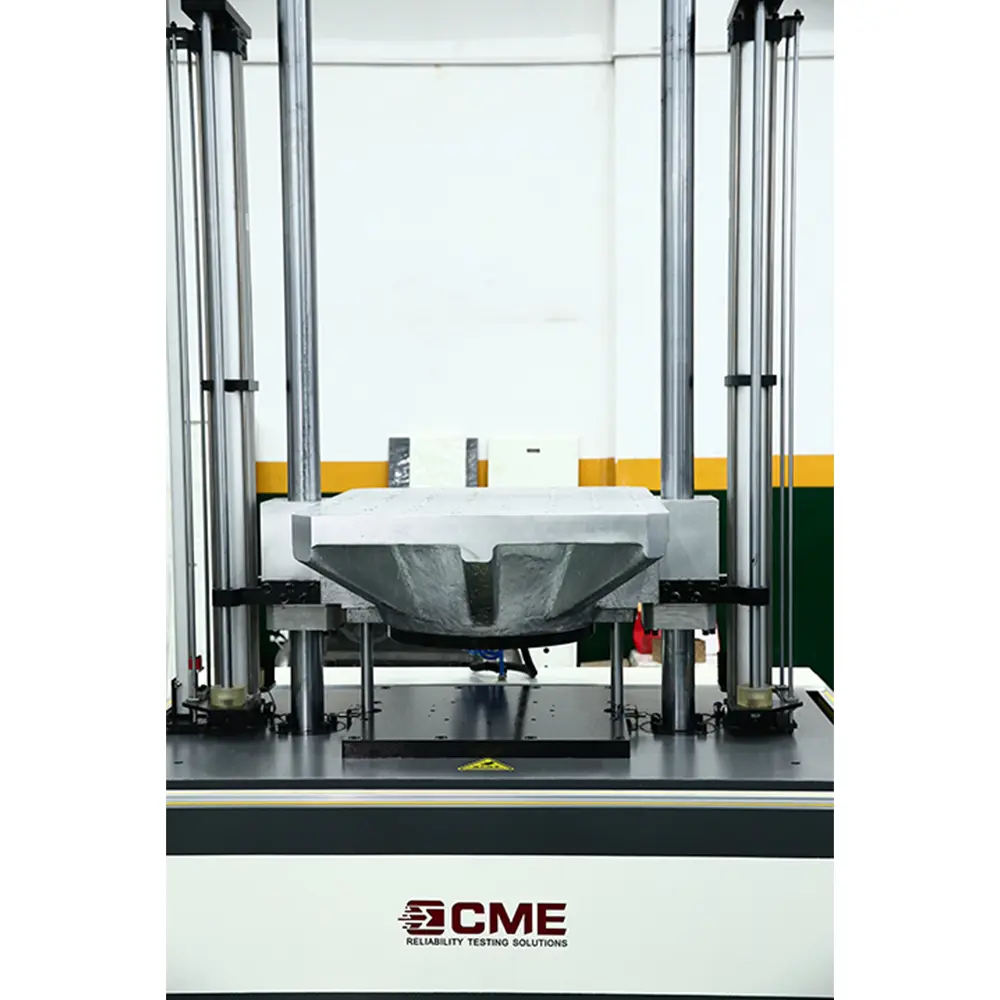

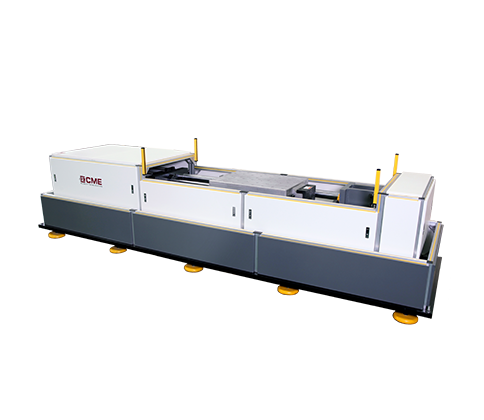

The basic body of the shock tester table is KRD10 series hydraulic lifting vertical shock tester, which is a free-falling vertical shock tester with hydraulic lifting and hydraulic braking. It is composed of shock table body, hydraulic source, electrical control, etc.

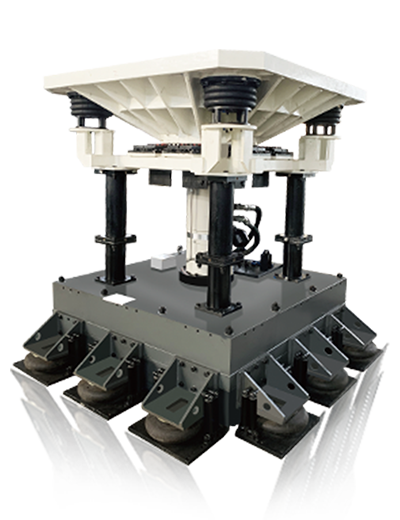

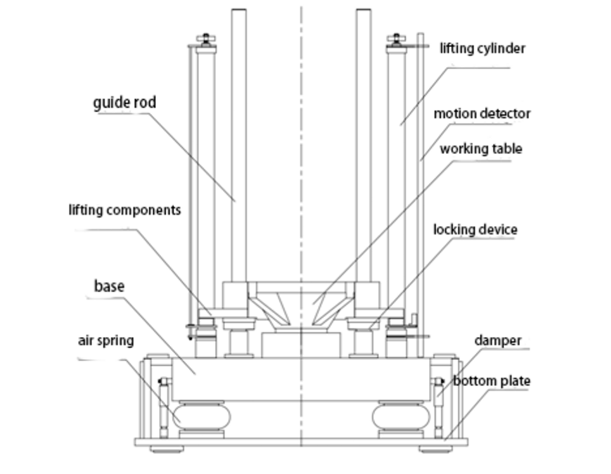

The table platform includes: working table, two guide rods, frame, air spring support system, lifting cylinder, displacement sensor, damper, hydraulic locking mechanism, etc.

The shock table adopts hydraulic drive, lifting cylinder lifting, high-pressure oil brake positioning, free fall, high-pressure oil-liquid brake to prevent secondary impact. The structure schematic diagram and pictures are shown in following figure: