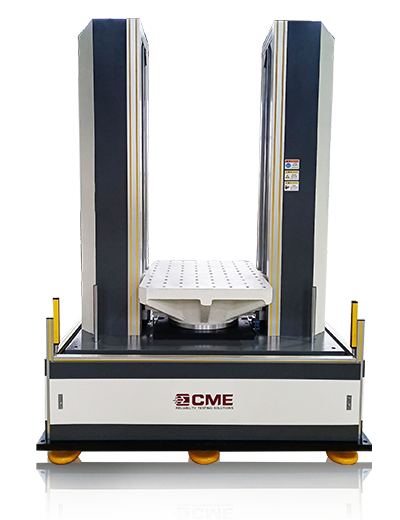

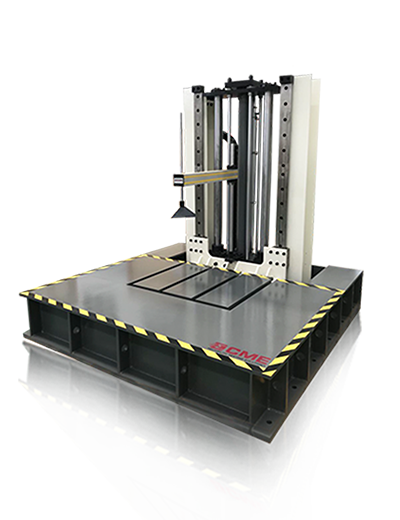

Multi-Axial Simulation Table (MAST) simulates the vibration of real-world environments in the laboratory. Element provides multi-axial vibration testing for a full range of vehicle components and assemblies, delivering the data that automotive engineers need to develop safer, more reliable, and dependable vehicles and their associated components.

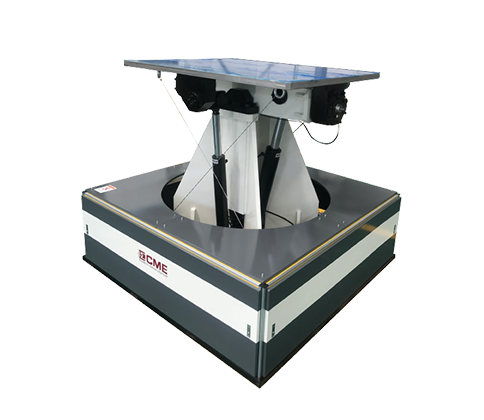

A multi axis simulation table is an automotive test system specifically designed for the high-frequency testing of vehicle components. It is sometimes also called a Multi-Axis Shaker Table or MAST table.

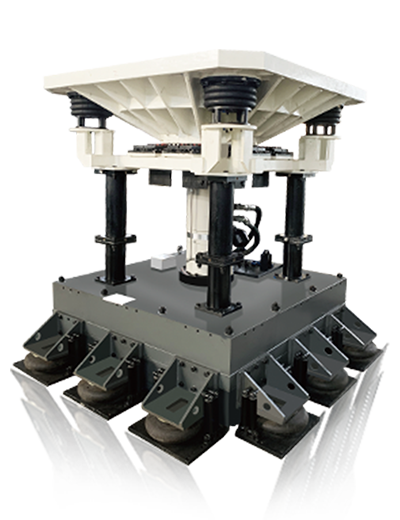

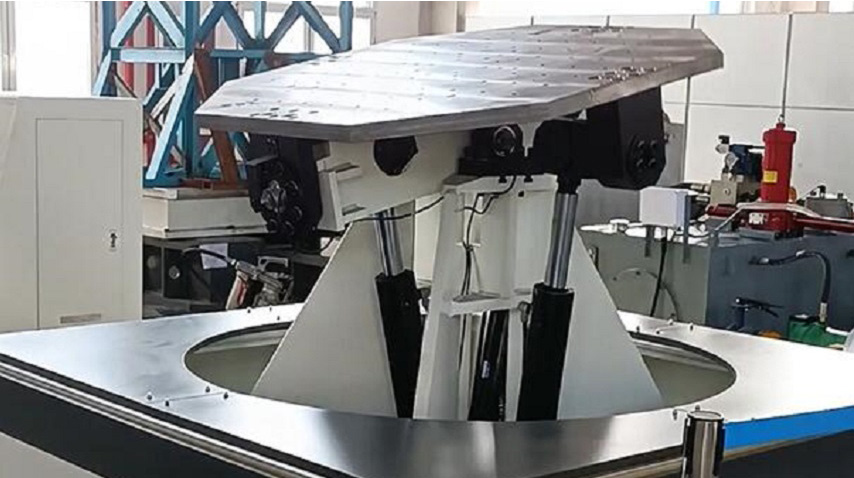

Multi axis simulation table can simulate acceleration and displacement outputs and reproduce key data collected on proving grounds, by providing a full six degrees of freedom (6 DOF).

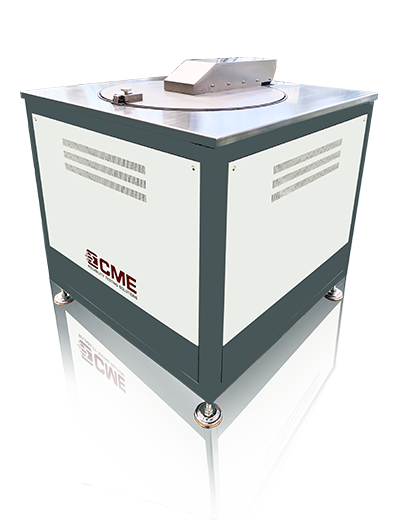

These test systems consist of a hexapod platform with a low resonance table on top. The test system can be used to simulate any kind of vibration in all six degrees of freedom.

The movements of the test system are tightly controlled by a digital test controller.

WHAT APPLICATIONS FOR MULTI-AXIAL SIMULATION TEST?

The Multi-Axial Simulation Table (MAST Table) is applicable for:

Seismic: earthquake testing

Aircraft, vessel, helicopters taking off and landing

Docking of spacecraft

Refueling of aerial tankers.

Automotive vibration

Simulation of ground, ship or floor movements

Imbalance in loading and unloading and wind

Long-term swaying of the ship

Modal analysis