TABLE OF KRD12 PNEUMATIC HORIZONTAL SHOCK TEST MACHINE

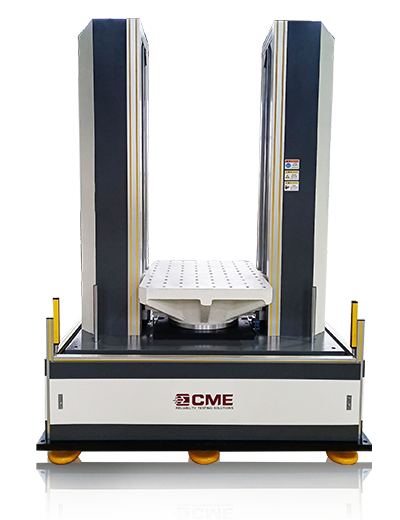

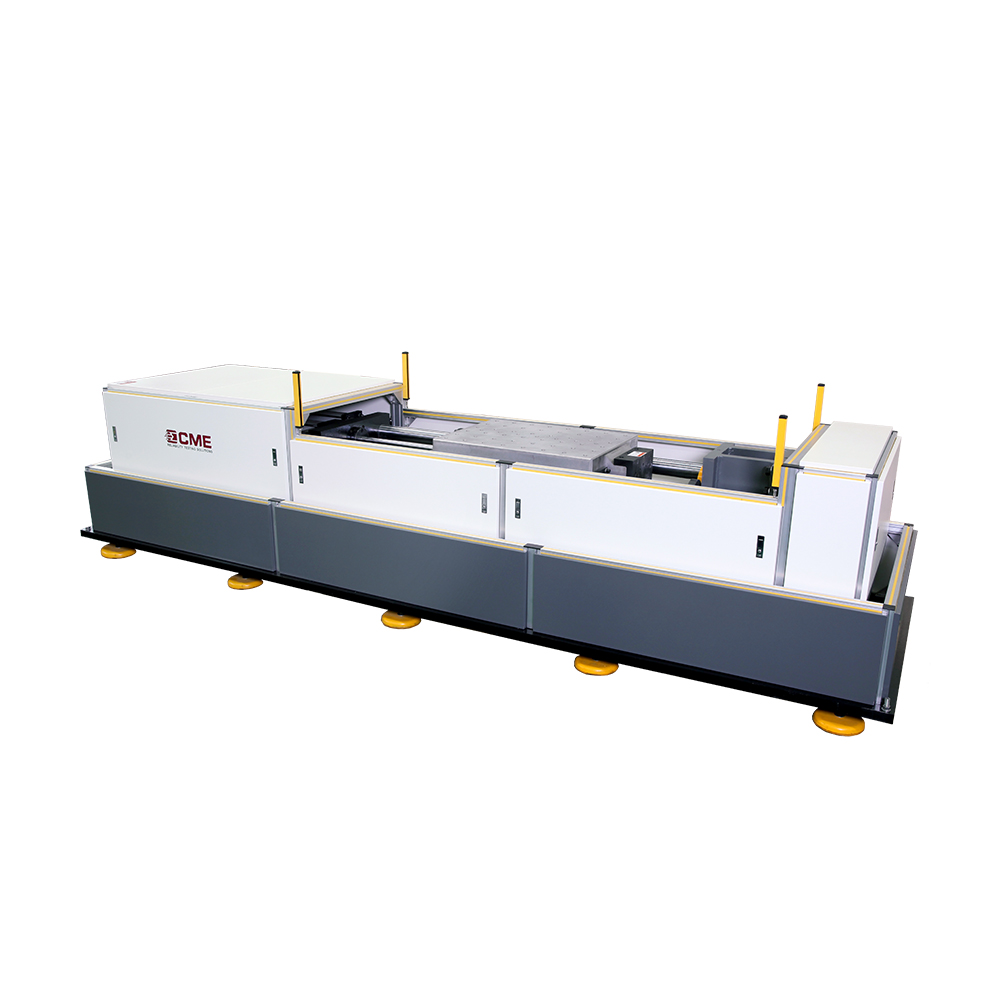

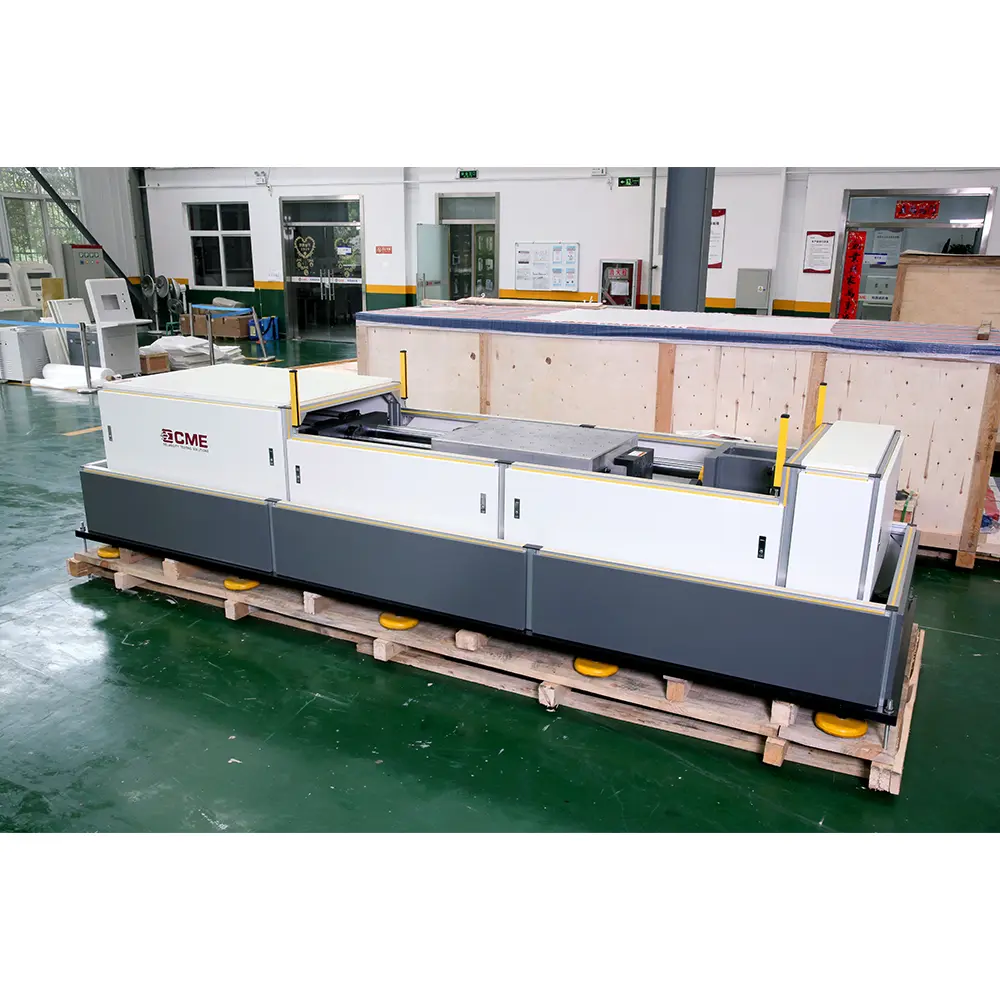

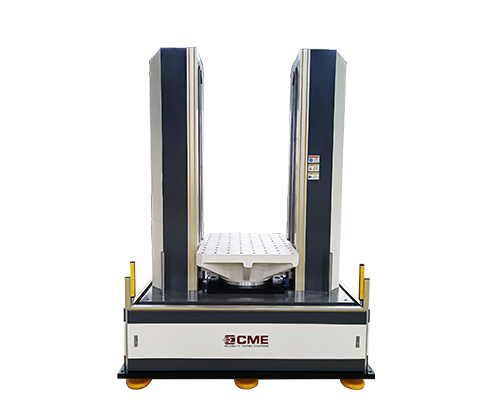

KRD12 pneumatic horizontal shock test system is composed of a test machine body, shock control measurement controller, pneumatic system, waveform generator, and other parts.

The shock table is a rigid structure, and there are mounting holes on the table, which are mainly used to support the test fixture. By changing the installation method or direction of the test product, tests in different directions can be carried out.

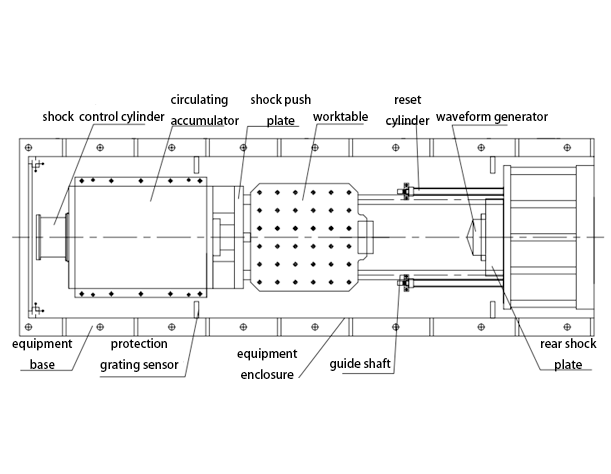

The pneumatic horizontal shock testing table consists of a working table, shock push plate, control cylinder, grating sensor, pneumatic self-locking mechanism, pneumatic return device, etc. The schematic structure is shown in the figure.