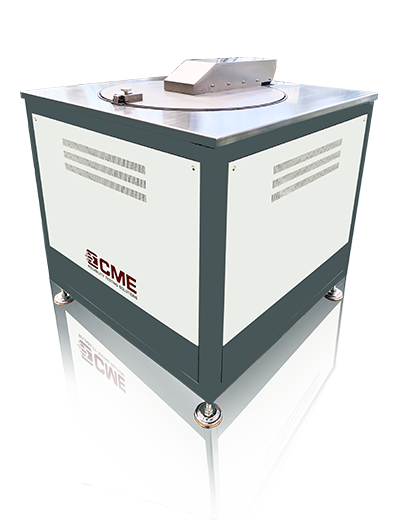

COMPOSITION OF KRD31 CONSTANT ACCELERATION TESTER

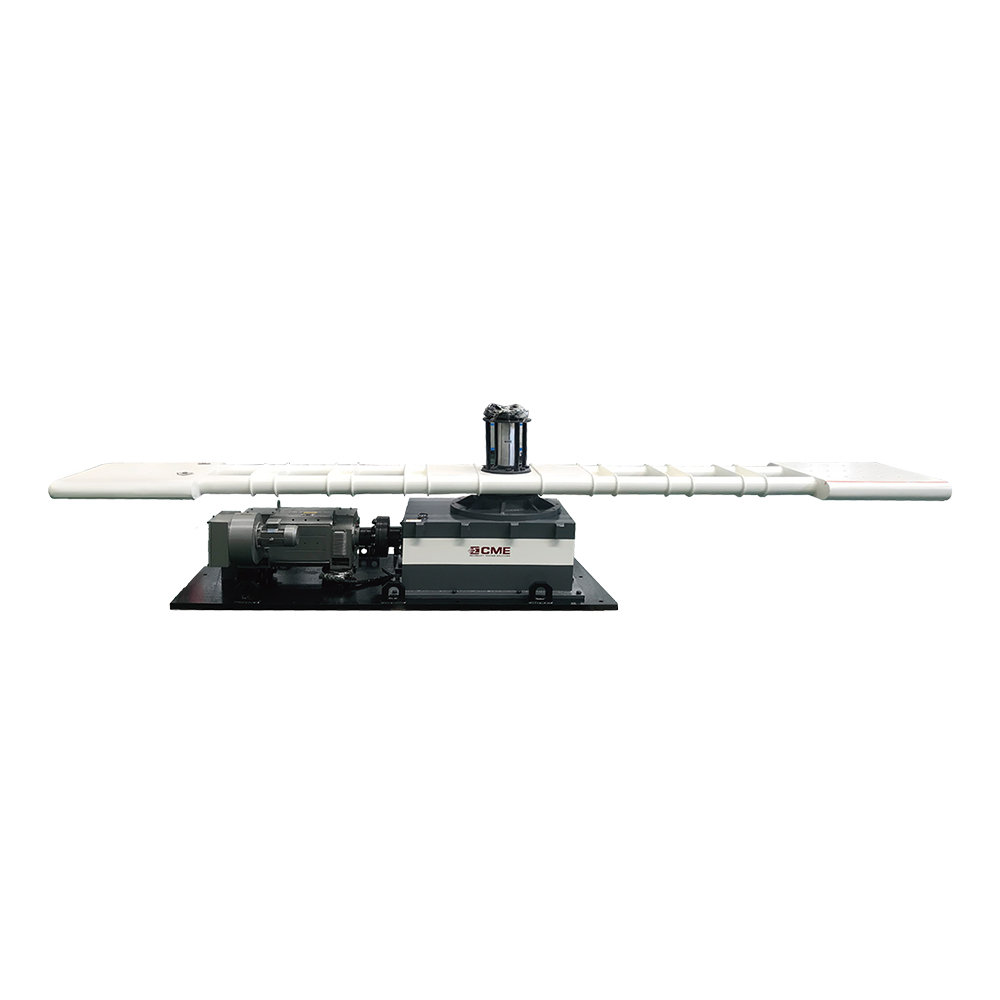

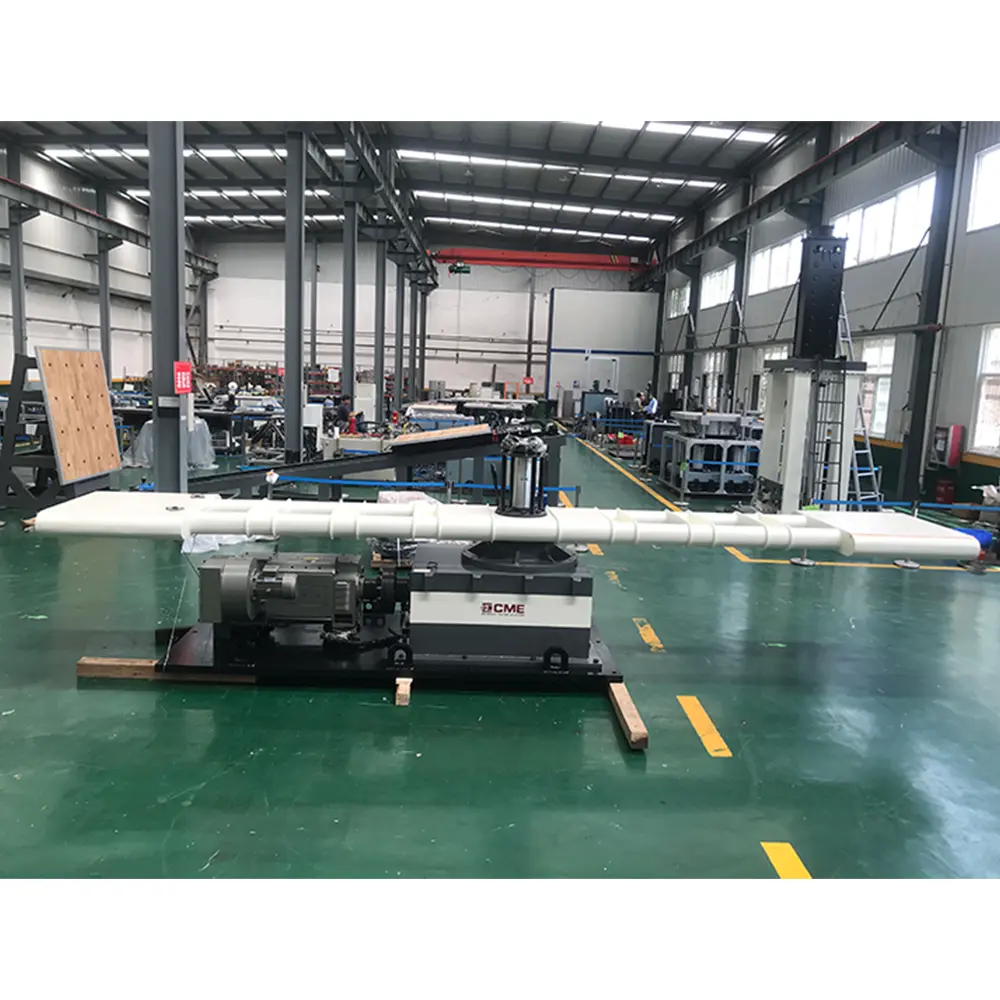

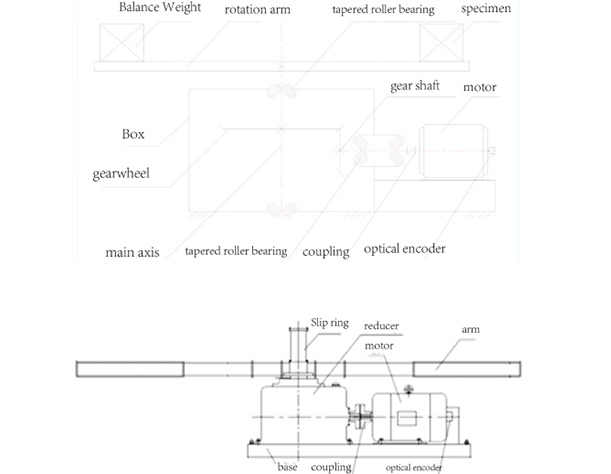

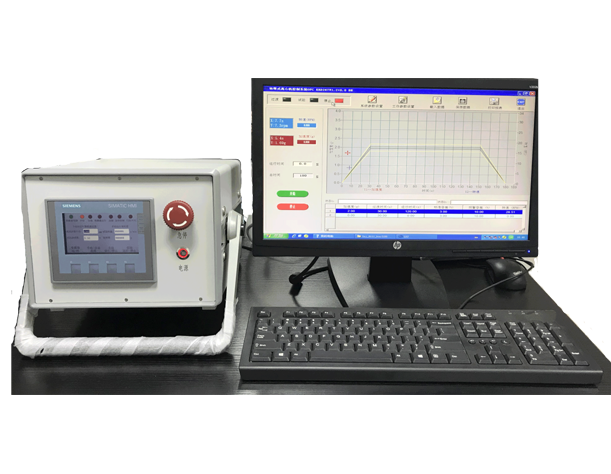

This acceleration test equipment mainly comprises rotating arm assembly, transmission system, box, base, frequency conversion measurement and control system, monitoring system, door control safety system, etc.

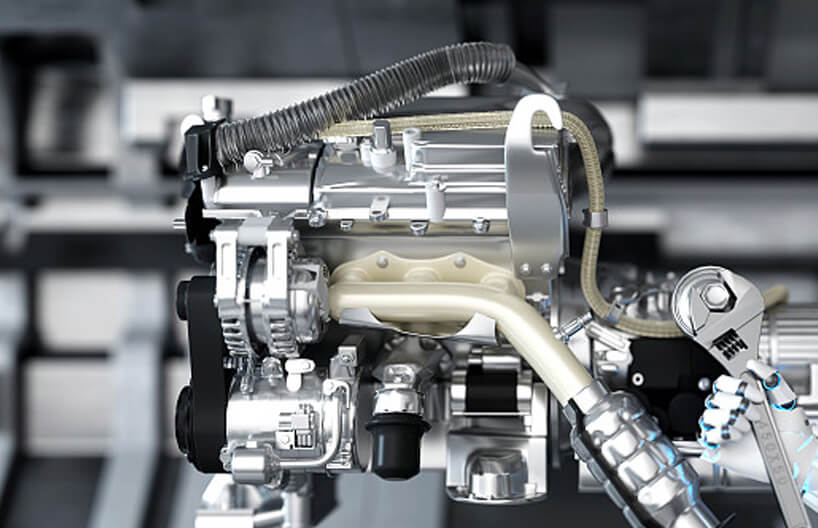

The constant acceleration test table includes slip ring, reducer, motor, arm, coupling, optical encoder, etc. The test in different directions can be carried out by changing the installation direction of the sample on the rotating arm installation plane.

The three-phase asynchronous motor drives a pair of bevel gears with a large reduction ratio to decelerate through a flexible coupling. The giant bevel gears are installed on the rotating main shaft, and the working arm is also fixedly connected to the rotating central shaft, thereby driving the working arm to rotate around the main shaft.