KRD17 series is a fully automatic pneumatic lifting and bidirectional shock test system. It is a vertical shock test system with novel design, high degree of automation, simple operation and convenient maintenance. It is the novel designed and developed for large specimens that cannot or are not easy to turn over. This mechanical shock machine can complete vertical upward and downward shock test in one test stand without moving the UUT.

It is especially used in the field of battery testing. The shock test equipment measures and determines the impact resistance of battery products without turning over the battery products, and assesses the functional reliability and structural integrity of the battery in an impact environment.

Circulating storage cylinder: strong impact, fast speed and low air consumption

Adopt full pneumatic drive: simple structure, high reliability, no pollution

Automatic control of lifting height: The software automatically lifts the console surface to the set height, with high accuracy and good repeatability. The height measurement is completed by the ultrasonic displacement sensor.

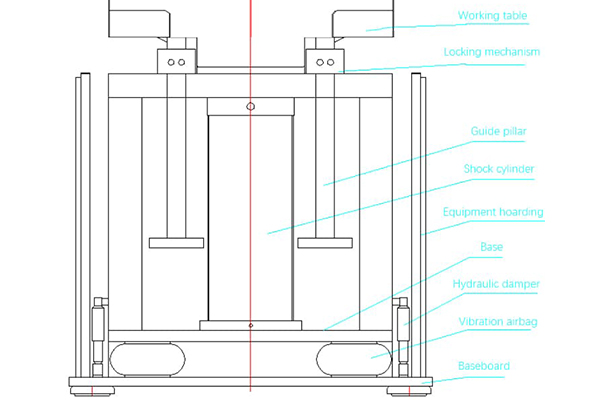

Multi-track guide pillar: combined with pneumatic balance lifting system, no noise, fully automatic positioning table

Free foundation: the equipment comes with high-performance buffer and vibration isolation device, no special foundation is needed, and it is easy to install

Bidirectional shock test: effectively complete the upward and downward shock tests without turning over UUT

This bidirectional shock test machine is composed of a circulating air storage cylinder, a pneumatic self-locking control mechanism up and down each, a forward impact plate, a reverse impact plate, a locking mechanism, a base and other parts.

CME also provides other shock and bump test machines for sale such as krd10, KRD 11, KRD 12, KRD 13, KRD 16 and KRD 20. Contact us for more information!