Internal metallization and lead system, die or substrate attachment, and other elements of the microelectronic device. By establishing proper stress levels, it may also be employed as an in-line 100 percent screen to detect and eliminate devices with lower than nominal mechanical strengths in any of the structural elements.

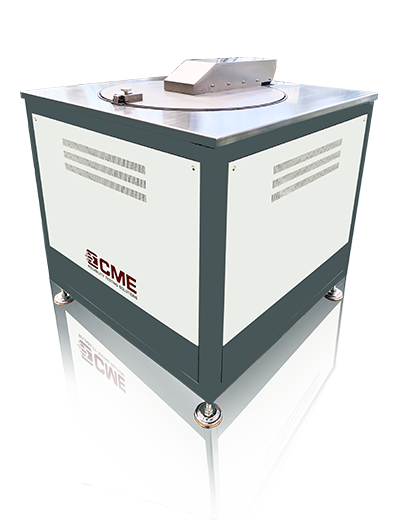

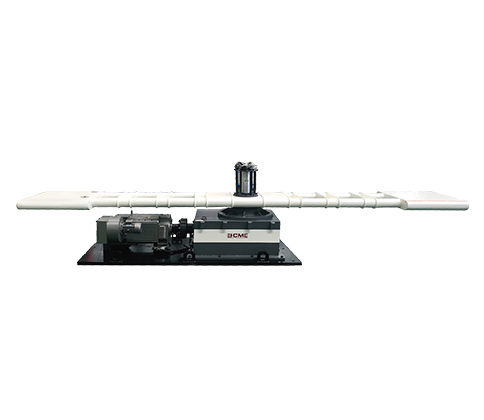

Centrifugal constant acceleration test is performed to evaluate when components, equipment, and other electrical and electronic products are subjected to a steady acceleration environment (except gravity) such as occurs in moving vehicles, especially flying vehicles, rotating parts, and projectiles, whether the structure adaptability and integrity are good, and obtain the units' electrical parameters.

The constant acceleration test equipment we provide can be used for avionics and military hardware testing, satellite component testing, R&D laboratory and system identification testing, product development, reliability, stress screening, etc.

Key Applications of Constant Acceleration Testing

Our constant acceleration test equipment serves critical roles in:

Avionics and Military Hardware Testing - Ensuring reliability in extreme conditions

Satellite Component Validation - Verifying space-worthiness

R&D Laboratory Testing - Accelerating product development cycles

Quality Screening - 100% inline testing to eliminate structural weaknesses