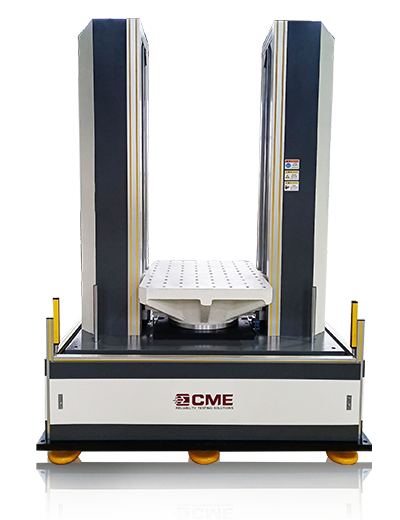

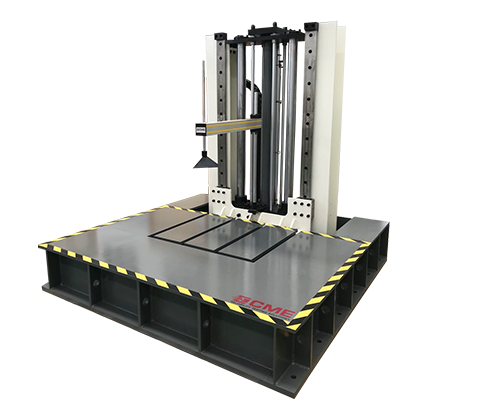

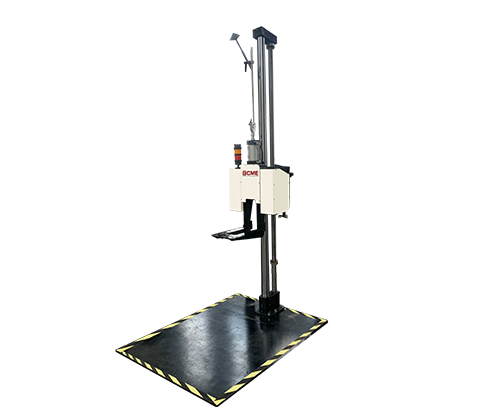

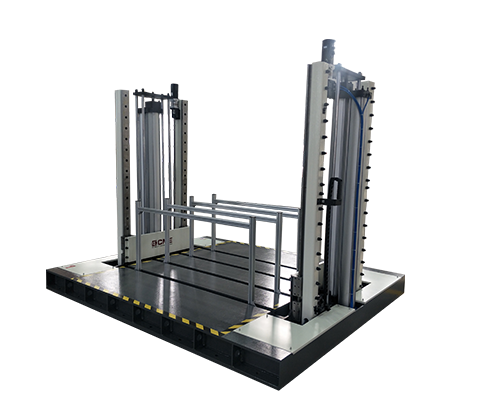

KRD40 series zero-distance drop tester mainly simulates the resistance to drop and impact of large and heavy packaging products. It can realize the drop test of the edge, surface, and angle of the sample. This equipment is mainly used to evaluate the ability of product or packaging to withstand drops during transportation and loading and unloading, so as to improve product and packaging design.

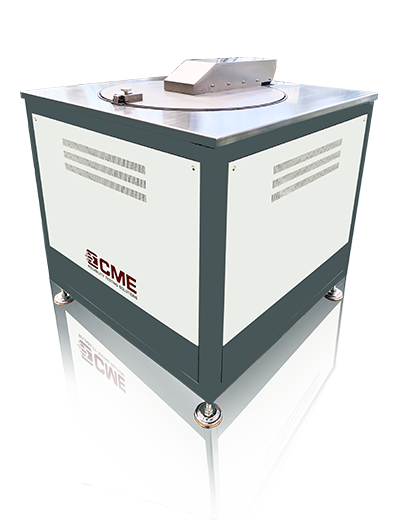

Drop testing is a critical reliability assessment that simulates the free-fall impacts products or packages may endure during shipping, handling, and accidental drops. This test is primarily conducted to evaluate and improve the robustness of product designs and the protective adequacy of packaging, ultimately reducing damage, returns, and costs in the supply chain.

As a leading drop test equipment manufacturer with over 16 years of expertise, CME Technology Co., Ltd. designs and builds a comprehensive range of drop testing equipment—from standard models to fully customized drop test machines—to meet global standards like ISTA, ASTM, and IEC.