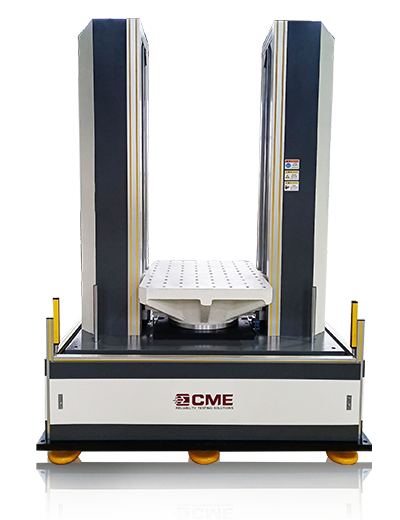

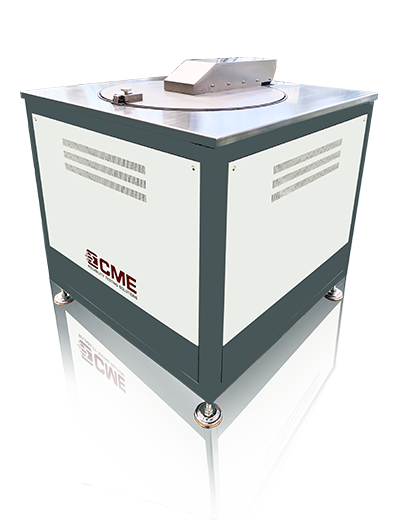

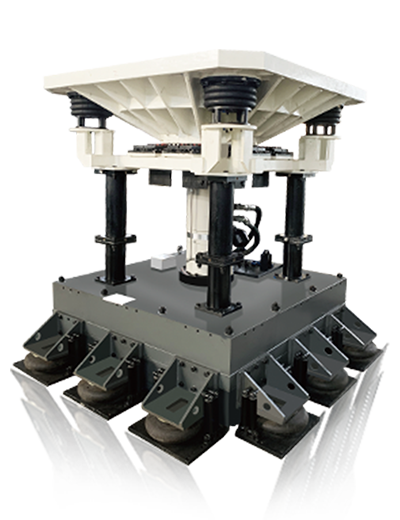

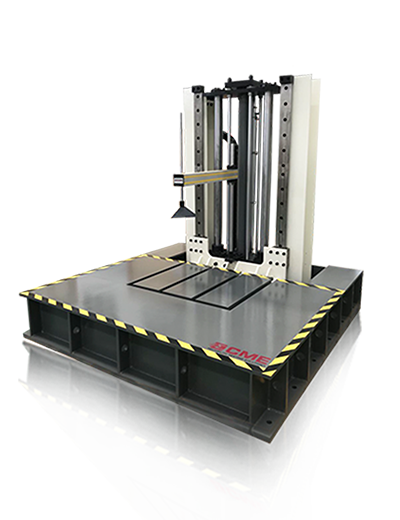

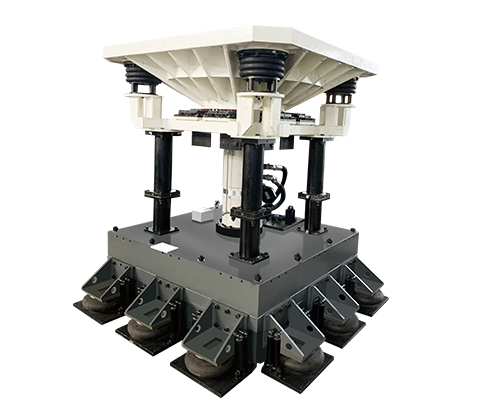

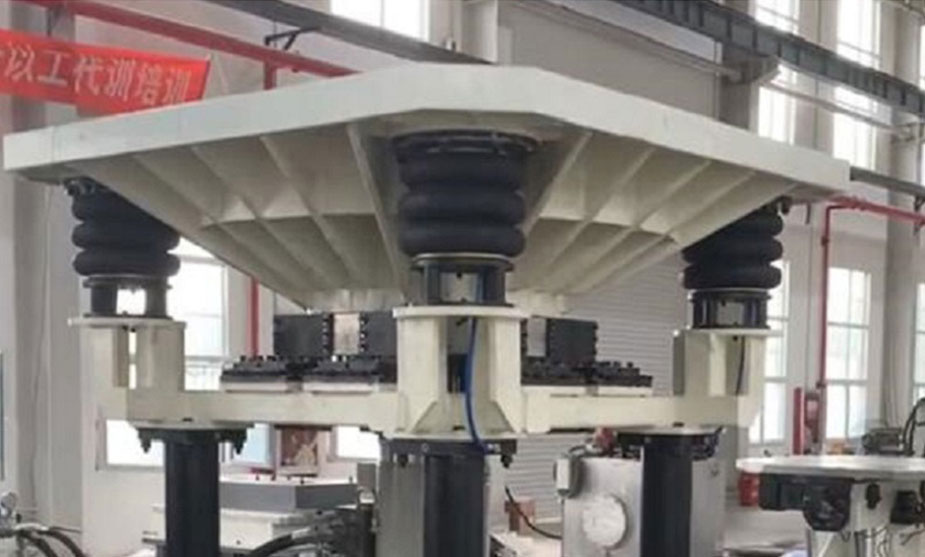

There are three types of shaker systems—electrodynamic (ED) shaker, servo-hydraulic (hydraulic) shaker, and mechanical shaker. CME offers hydraulic vibration shaker for sale. The major specifications to consider are frequency range, displacement, acceleration, tested axes, payload and vibration/shock levels, and force rating. Since mechanical shaker can only test sine and was out of date, we discuss the other two types.

Vibration testing is simulating the vibration environment by the shaker in the laboratory, introducing force function into the UUT to test the response of the UUT to a defined vibration environment. Vibration testing is performed to test the product's durability, integrity, fatigue life, and resonant frequencies.

As one of the most professional vibration shaker manufacturers in China, CME offers mechanical vibration shakers worldwide.

Vibrations testing is one of the most important reliability tests for a variety of industries. Many industries require their own standards to access the damages caused by vibrations and qualify the product. Following are the standards categorized by CME.

Compliant with Global Testing Standards

Our vibration testing shakers are designed to help you meet rigorous industry and military standards, including:

MIL-STD-810G/H (Environmental Engineering)

IEC 60068-2-6/64 (Vibration & Shock)

ISTA Series (Packaging Testing)

ASTM D999 (Container Vibration)

ISO 16750 (Road Vehicles)